Environment

Phihong deeply recognizes the importance of Earth's resources and sustainable development. The company actively promotes environmental management systems and aligns with global carbon reduction trends. Using 2021 as the baseline year, Phihong aims to achieve a 42% reduction in carbon emissions (Scope 1+2) by 2030, working toward net-zero emissions by 2050.

Green Research and Development

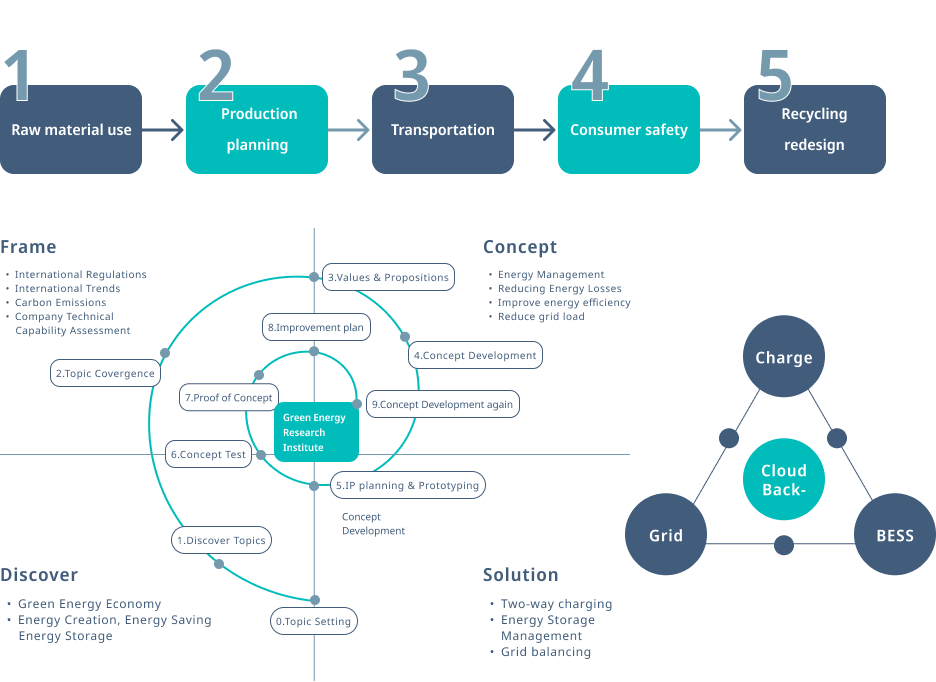

In 2021, Green Energy Research Institute was established to grasp the market demand with green energy sustainability as the main focus, and to implement forward-looking lowcarbon technology expansion to create maximum profits for the company.

With the extension of the original AC/DC fast charging technology, the main research items are energy storage, conversion and management. Mainly effective energy management to achieve more efficient energy use to save energy waste and improve the efficiency of charging and energy storage.

The Green Energy Research Institute’s i-Green Charging Solution Technical Center (i-GCSTC) continues to develop advanced technologies and manufacture high value-added green energy products.

One of the important factors in the popularization of electric vehicles is how to solve the user’s anxiety about charging, and the direct water-cooled high-power power supply charging system meets the charging trend of customers.

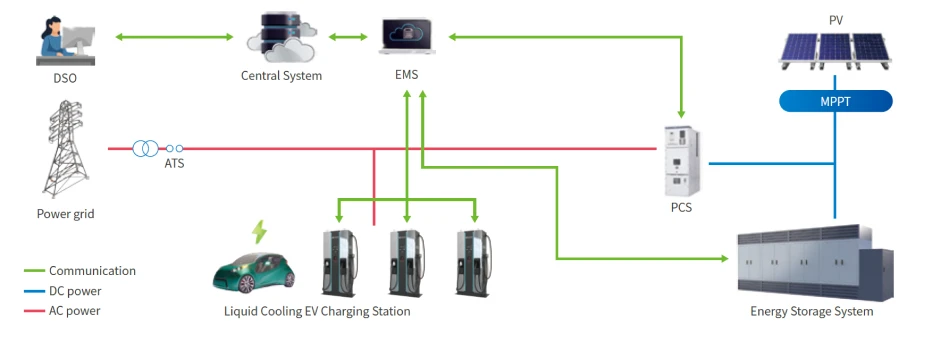

In addition, the electric vehicle power is fed back to the grid or storage system to form a smart power network, and the storage system and energy management system with active battery balancing can increase the green energy usage rate and regulate the peak/off-peak power to increase the power usage efficiency.

The electric vehicle’s power will be fed back to the grid or storage system to form a smart power network.

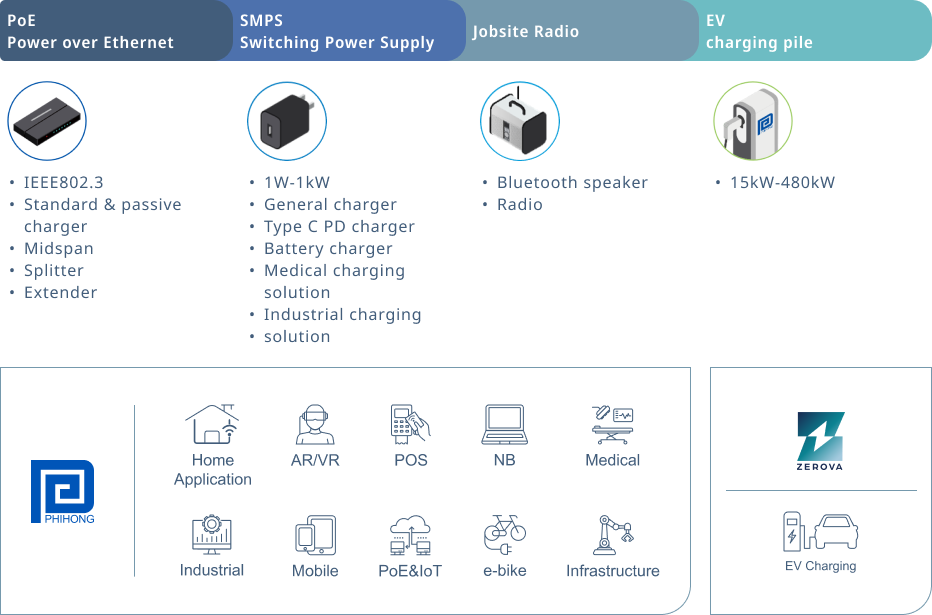

The third-generation semiconductors GaN/SiC enable product designs to achieve at least a 50% increase in power output while maintaining the same size and improving overall energy efficiency. This means delivering 150% power output with the same compact size, offering a lightweight advantage and breakthrough high-power design features. The new GaN-based adapters/chargers incorporate multiple safety protection mechanisms, significantly enhancing safety and compliance with industry-standard regulations. These innovations align with the trends toward high power, miniaturization, and lightweight designs.

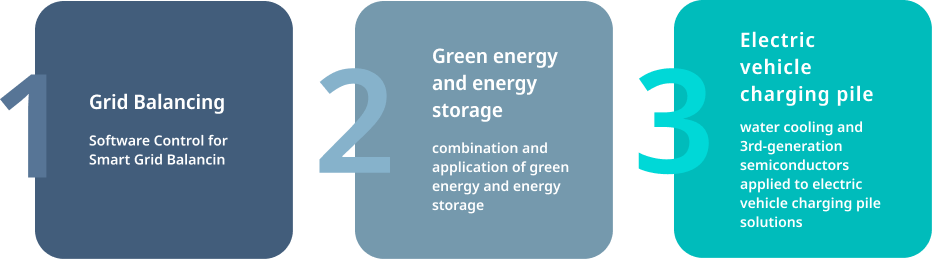

1. Research and development of water-cooled charging technology:

Power module design and water-cooled cooling system research and development design. Water-cooled technology can improve heat dissipation, extend the life of the charging system, and reduce noise and sound pollution. Moreoever, the water-cooled isolated air technology can achieve the safety level of application for explosion-proof Zone 2, which can be directly installed in the existing gas station area to facilitate future urban development.

2. V2H / V2G power development and bi-directional controller design:

The next 2025 regulations require bi-directional charging systems that can be fed back into the grid or used for home/industrial energy storage charging. We will not only implement green design, but also extend this sustainable direction to R&D concept and manufacturing, and strengthen energy-saving management to achieve the purpose of reducing energy consumption, environmental protection and sustainable development.

3. Research and development of energy storage technology:

including control board design, active balancing design, power supply design, energy storage system and charging system integration design. Develop active balancing technology and combine energy storage & charging technology with software control.

4. Research and development of grid balancing technology:

including power integration technology, small-scale energy storage grid management system algorithm.

In the future, the electricity from electric vehicles will be fed back to the grid or fed back to the energy storage system, which will be used to become a regional power network and effectively use the electricity to become a smart grid.