Employees

Phihong believes exceptional talent drives sustainability. We are dedicated to creating a LOHAS (Lifestyles of Health and Sustainability) workplace that respects human rights, fosters employee happiness, and enhances job satisfaction and belonging.

Employee Health and Safety

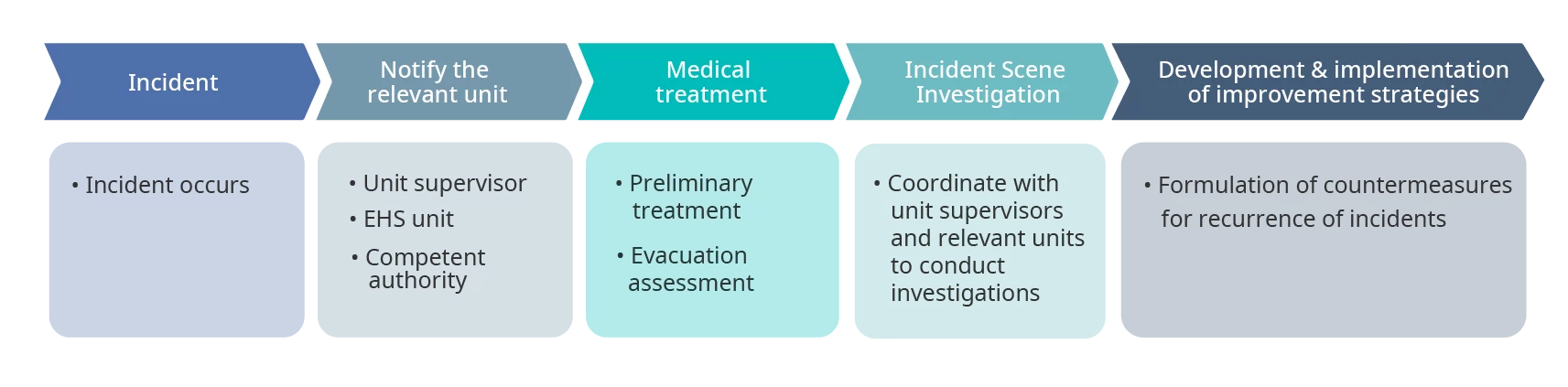

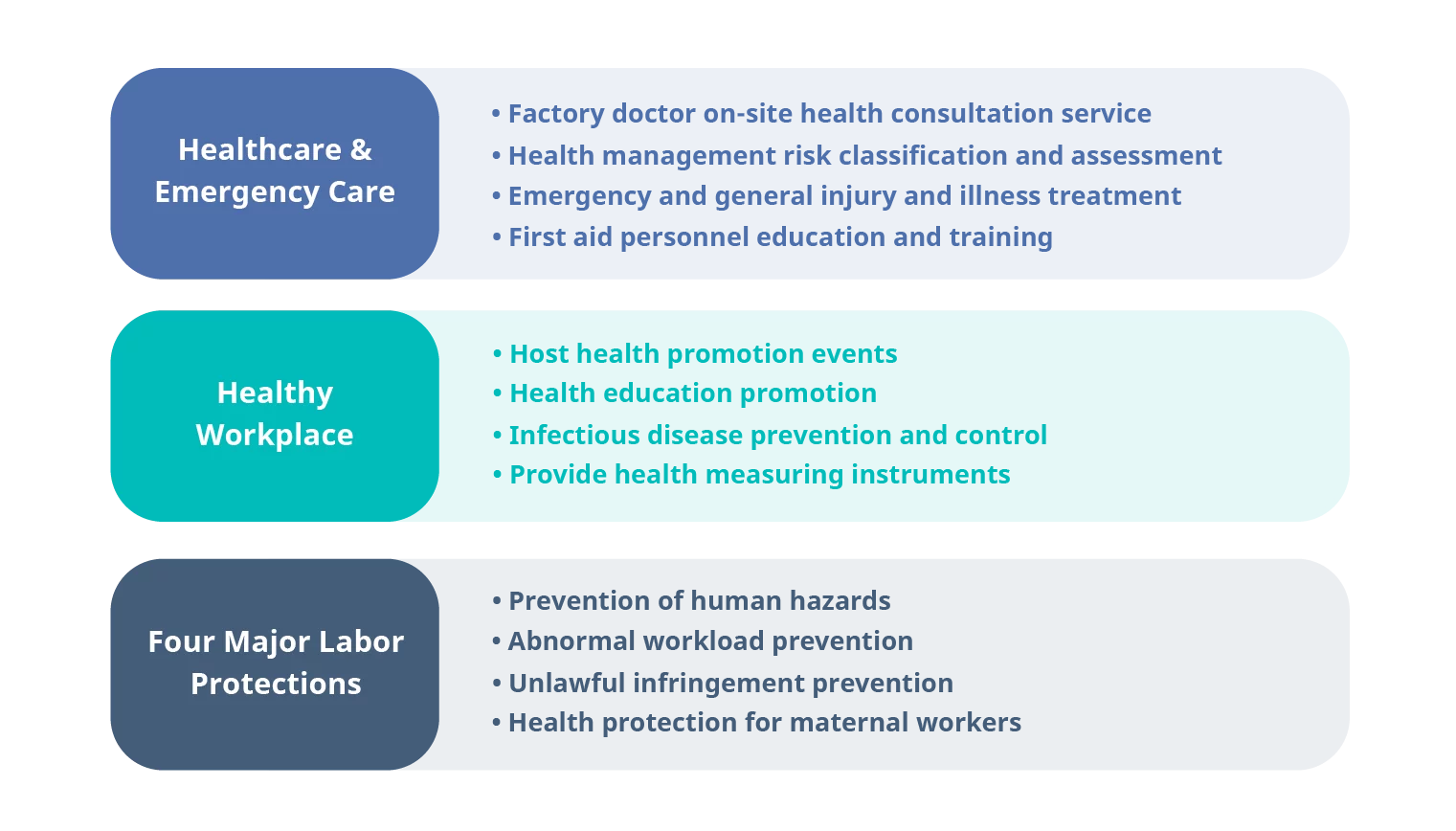

To ensure factory safety, work environment, and employee health, Phihong integrates occupational safety and health management into its key strategies for sustainable development. We have formulated an “Environmental Safety and Health Policy” and established an Occupational Safety and Health Committee in accordance with the “Occupational Safety and Health Management Regulations.” This committee drives the occupational safety and health management system, undergoes annual verification, and strives to create a healthy and safe workplace for employees. To prevent occupational accidents, we thoroughly inspect and supervise workplace safety, aligning with local government regulations and company policy requirements across all factory locations.

To prevent hazards to personnel safety and health, as well as potential financial losses to the company due to operational activities or services and facilities, Phihong conducts continuous hazard identification and risk assessment. This includes implementing appropriate preventive measures, executing necessary control methods or hazard elimination, and identifying opportunities for improvement to keep risks within acceptable limits. Additionally, every three years, comprehensive hazard identification and risk assessments are conducted for all current, potential, and temporary changes in operational activities within the plant and external hazardous materials. A baseline review team, trained in process safety assessment, uses semi-quantitative and qualitative methods to assess and classify identified risks. Based on this classification, control measures are established according to graded controls, occupational safety and health objectives, and management plans. These measures include elimination, substitution, engineering controls, signage/ warning systems, administrative controls, and personal protective equipment, prioritized to reduce risks. The goal is to seek optimal risk reduction solutions and continuously improve them. For employees engaged in operations with high incidence rates of occupational diseases or high risks, appropriate personal protective equipment is provided. Health checks to prevent occupational diseases are arranged, and workplace environmental monitoring is conducted. Abnormal monitoring results trigger follow-up management and necessary individual health consultations, care, and guidance.

| Risk Level | Risk Score | Risk level description | Management principles |

| Level 1 | > 100 | Listed as a significant source of risk and tracked for improvement | The risk level value greater than 100 and the severity of the consequences greater than or equal to 10: identified as an important risk source, included in the "List of Important Hazard Sources and their Control Measures". The methods of control and improvement are: elimination, replacement, engineering control improvement, etc. |

| Level 2 | 81~100 | Significant risks that need to be controlled through corrective actions | Risk level values 81-100: If the hazard source has implemented operation control on the existing basis and there are improvement measures to control it, there is no need to upgrade the occupational safety and health OHS management plan. If the hazard source has not implemented operation control or can continue to reduce the risk of injury, Then it is necessary to raise the target improvement plan and control |

| Level 3 | 51~80 | Risks that need to be controlled through training and production safety regulations | Risk level values 51-80: Control through education, training and production of safety practices |

| Level 4 | 21~50 | Risks that need to be controlled by labeling | Risk level values 21-50: Controlled by warning signs and use of protective equipment |

| Level 5 | ≦ 20 | Acceptable risks | Risk level value less than or equal to 20: Acceptable risk, just keep watching |